Solutions adapted to fresh food packaging in trays on supermarket shelves, such as meat, poultry, fish, gastronomy, fruits and vegetables in large-scale retail shops. Stretch packaging helps protect and store products through the use of a highly sensitive film (stretch) that is wrapped around the product itself or the tray that contains it.

This feature allows the user to package any tray or product using a single width film reel with considerable advantages both in terms of management and cost saving.

The machines operate on continuous cycle.

The film, directly taken from a reel, is formed into a tube by the folding box, and sealed underneath by a series of sealing and driving rollers.

Products manually and/or automatically placed between the pushers of the infeed conveyor, are introduced into the tube of film.

The sealing jaws provide a cross seal with central cut, separating the products.

The final pack is then conveyed onto the discharge belt for the following packaging stage, either multipack or boxing.

The machine can operate:

–With neutral or continuous print: The fixed length of the bag will be set into the machine control panel;

–With print registration: The length of the bag will correspond to the distance of the spots on the film.

The Tray Sealing Machines can be used to package in a modified atmosphere as well as perform simple only sealing, Skin effect packaging and vacuum packaging.

Reliable machines with a productive output able to satisfy the needs of large industrial companies, flexible and easy to use, can also be used in large-scale retail shops.

Modified atmosphere packaging (MAP) keeps the original organoleptic and nutritional characteristics of fresh food products unaltered for a longer time.

The result is an extended shelf life without the addition of chemical preservatives or stabilisers.

The technology of packaging is created through the use of the formed rigid film onto which is sealed the flexible film, providing to the product inside a additional protection against the external agents.

The forming and sealing chambers are strictly aluminium made from a solid piece, they are handled by electric or pneumatic systems and supported by study oversized leveraging mechanisms.

We offer machines for flexible, semi-rigid or rigid base film up to 900μm.

Each package is completely customisable in terms of size and shape.

Packaging can be involve sealing only, vacuum, modified atmosphere, skin and skin protruding

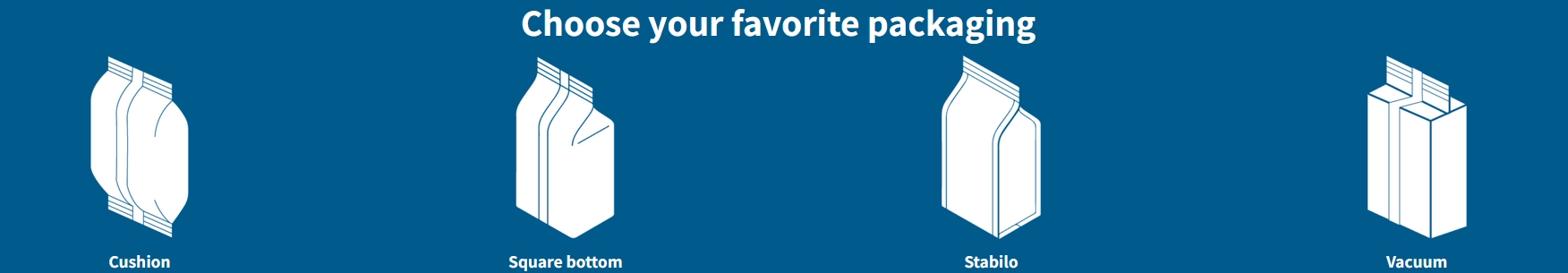

This machines are able to pack your product trhought a vertical system of packaging, the machines are designed for use flexible packaging material wrapped around the forming tube, which is then filled vertically with product and sealed in a sequence of operations.

Vertical Form, fill and seal machine machine which uses flexible packaging material to form a tube, which is then filled vertically with product and sealed in a sequence of operations whilst the packaging material is transported vertically downwards.

Those solutions are able to provide 4 several types of packaging:

-Pillow Bag (Cushion)

-Square Bottom

-Stabilo

-Vacuum

The dosing systems are able to match the target weight of the product that is set in the each program, automatically. Once the correct dose of product is reached, the machine discharge the dosed product automatically into the packaging machines, or through a discharge pedal activated by the operator.

Different types of dosing units are available, according to each specific product and required capacity, including:

-Multihead weighers

-Linear dosers

-Volumetric auger

-Piston Filler

The dosing system technology may be combinate with almost all types of packaging solutions, including:

-Vertical packaging machine

-Thermo sealing machine

-Thermo forming machine

-Flowpack machine

…..and other packaging machines

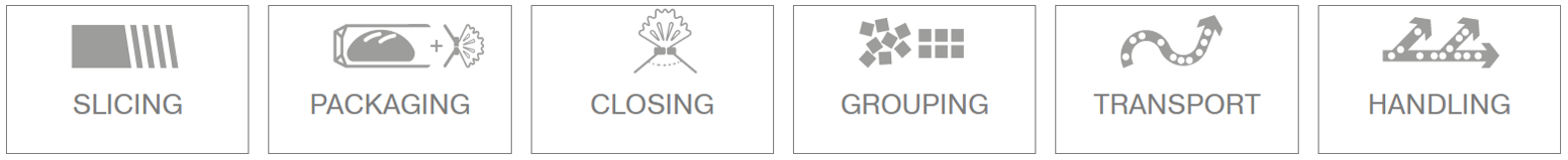

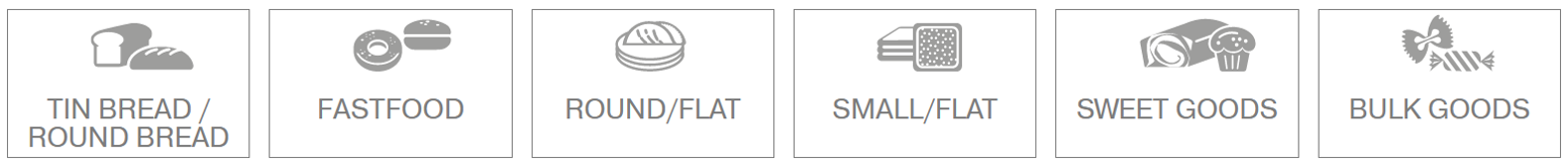

GHD Hartmann is leading manufacturer of technologically advanced machines for the bakery industry.

With the cooperations of GHD HARTMANN as our main supplier for the bakery segment, we are able to provide the followed solutions for your product.

Solutions for your bakery product:

For the followed category:

Vacuum packaging extends the shelf life of products, guarantees quality, prevents products from drying out, protects products from outside influences and improves hygienic handling.

Extremely reliable machines; They satisfy the needs both of small users and of thse operating on a large scale.

These machines are designed especially for closing with metal clip or throught thermoseald fruit and vegetable in tray or without several categories of product.

Processing machines for Fruit and Vegetable are able to cut them into:

– Cubes

– Strips

– Slices

– Grating / Shredding

We provide also solution to squeeze automatically the Citrus or Pomegranates.

All of these such applications for Fruits and Vegetables are destinated for food industry or retails.

We can provide turnkey solutions, including equipment for fish,poultry or meat slicing, fruit and vegetables processing and much more.

The quality control system can optimaze your automatized system with this special applications:

–Metal detectors: inspect the product, checking for ferrous and non-ferrous metal contaminants with BRC standard-compliant accuracy, rejecting defective parts from the production line.

–X-ray: inspection systems base their operation on diff erences in density and, therefore, on the diff erent ray absorption levels of objects unrelated to the product.

–Check weighers: Very sensitive and compact high-speed machines, suitable for weighing of wide range of products. The accuracy of checkweighers minimises overfi ll waste and, therefore, increases productivity.